Fire Sprinkler Systems

Detect,

Alert,

Control,

Extinguish.

Sprinkler Systems

Detect, Alert,

Control, Extinguish.

From evaluation and design, right though to handover and ongoing maintenance – our experienced and certified fire engineers have got your fire sprinkler system under control.

Your fire sprinkler system is in safe hands with Automatic, who have been at the forefront of fire engineering in Ireland for four decades and achieved the highest level of accreditation in the industry.

We hold LPCB 1048 Level 4 Certification which permits us to self-certify all of our works in all types of sprinkler systems.

Our expertise means you are assured that every aspect of your sprinkler protection project is taken care of in-house at Automatic. We work with you through the stages of conception, tender, approvals, fabrication, procurement, installation, testing, handover and follow-up service maintenance and inspecting to ensure you get the best possible fit for your requirements.

We have all the necessary skills in-house to provide you with a single source of contact that is reliable as well as responsible and responsive to your business.

We understand that the fire protection industry is constantly evolving (from design code planning regulations to insurance requirements to new technologies), and we are committed to adapting our skills and structure to deliver the best systems to suit your requirements and budget.

We have extensive experience in all internationally-recognised design codes including:

• EN 12845 Sprinkler Design Codes

• LPC /BSEN 12845 Sprinkler Design Code

• BS 9251: 2014 Residential and Domestic Sprinkler Systems

• FM Global Design Codes

• NFPA Sprinkler Design Codes

• Water Mist Systems To FM Global, NFPA, B.S. Vds, CEN Design Standards

You benefit from our expertise in a broad range of fire-fighting systems including:

Automatic Sprinkler Systems (Wet & Dry Pipe)

ESFR Sprinkler Systems

Deluge Systems

Pre-Action Systems

Foam Water Sprinkler/Deluge Systems

High & Low Pressure Watermist Systems

Sprinkler Fire Pumps & Tanks

Hydrant & Fire Main

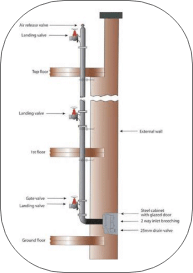

Wet & Dry Riser Systems

Our Fire Sprinkler Systems

Our Sprinkler Systems

FAQ’S